Fast food is big business. If you can get your products into one of the big chains you’ve got it made. Unless of course your product doesn’t come up to scratch.

That’s exactly what happened to one of our clients – a supplier of chicken parts to a well-known fast food company. Thanks to our statistical consultancy service we prevented the chicken parts supplier from being delisted by the fast food company and even helped them become the gold standard for other suppliers to emulate.

Size matters

The problem for our client was all related to the size of the chicken parts they were supplying. The company was threatened with delisting by the fast food business owing to size variation. That’s because the size of one of the parts supplied was frequently outside the agreed specification.

Taking a closer look

Our consultant Sam Turner visited the chicken parts supplier to find out what was going wrong and come up with a solution. It turned out that the chickens were mechanically butchered, the chicken parts were than routinely measured and if the parts were outside the specification, adjustments were made to the process by operator judgement. Unfortunately, the operator’s judgment was not reliable enough, leading to unacceptable size variation.

Statistical Process Control (SPC) saves the day

The answer was to develop a statistical control method. Sam devised a Shewart control system to replace operator judgement with a set of control rules which gave a clear indication of when adjustment was needed, and by how much.

Past data leads to a golden future

The Shewart control system was set up using past data, so no extra data gathering was required by the chicken parts supplier. Just as important there was no need to change the mechanics of the chicken butchering process.

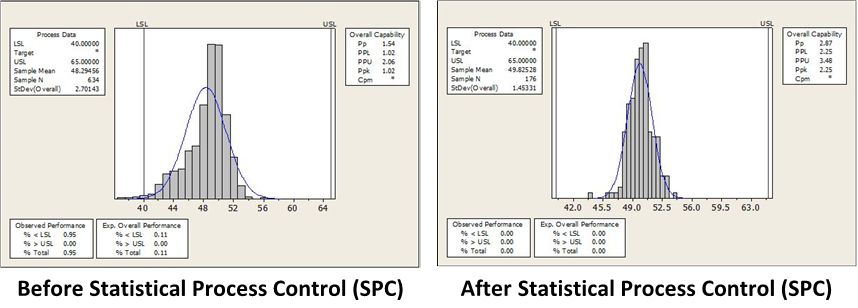

The following diagrams show the improvement that was made to the variation in size of the chicken parts. The fast food company was totally satisfied with the improvements, which meant that the chicken parts supplied were always within the agreed specification. Subsequently the fast food company used the chicken parts supplier as the gold standard for other suppliers to emulate.

Find out More

If you would like to know how our statistical consultancy service can help your company improve processes to save money and increase profits, please call us today on +44 (0) 1423 865955

To find out more about how Statistical Process Control can help your company to assess and improve a process, to achieve far better quality and considerable cost savings, book now for our “Statistical Process Control” course.